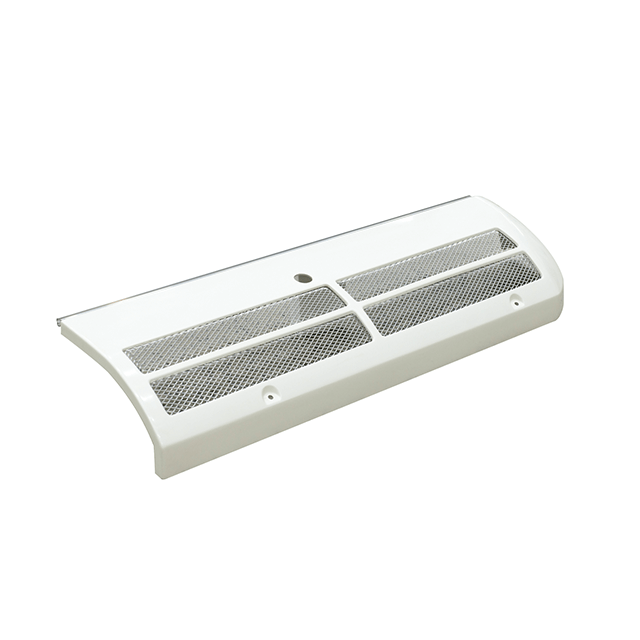

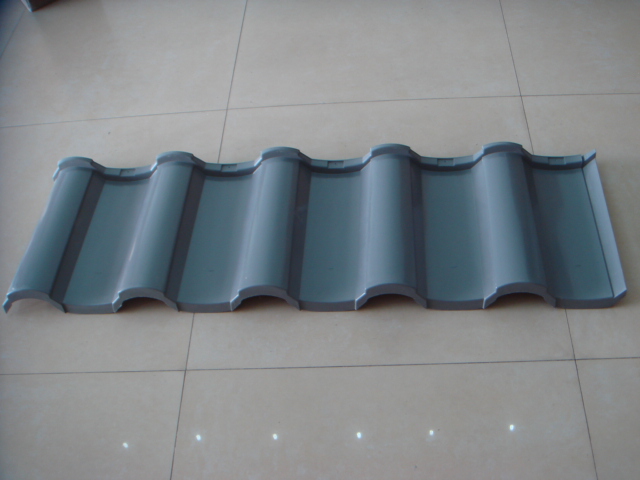

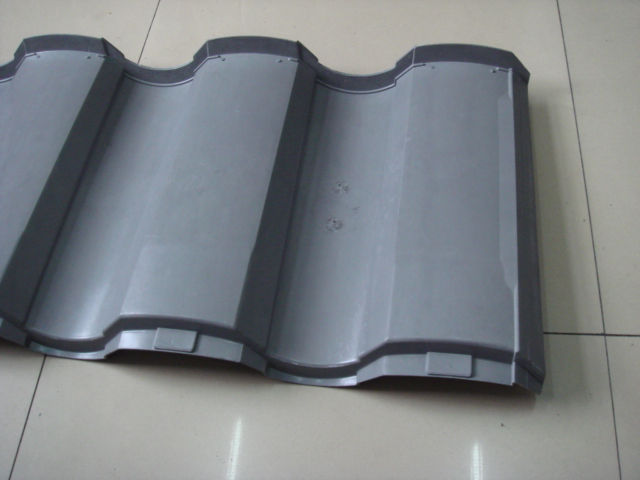

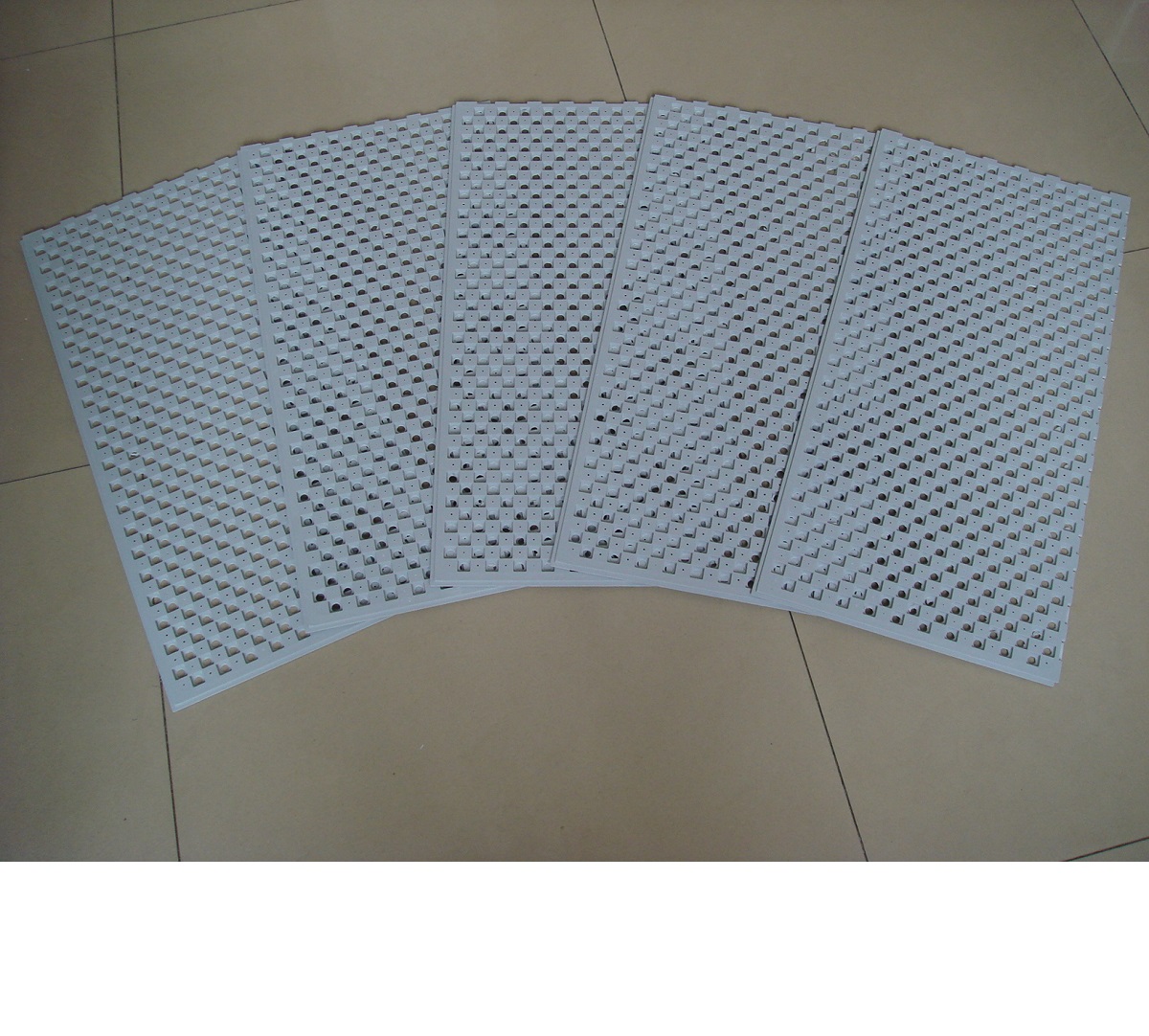

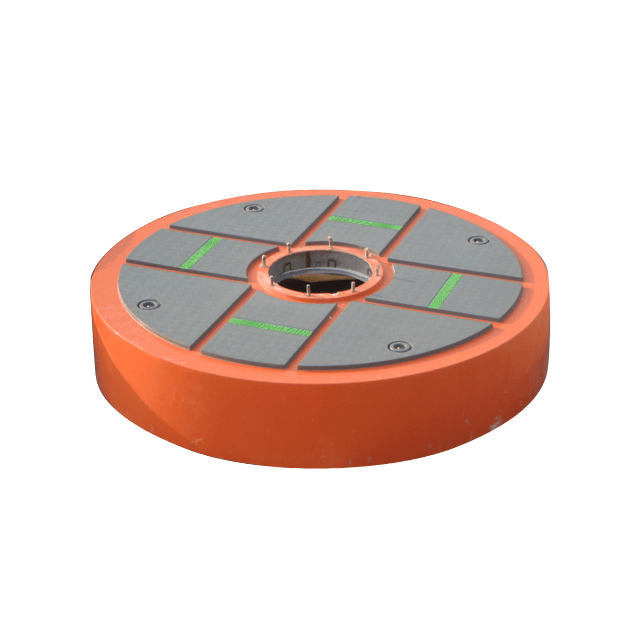

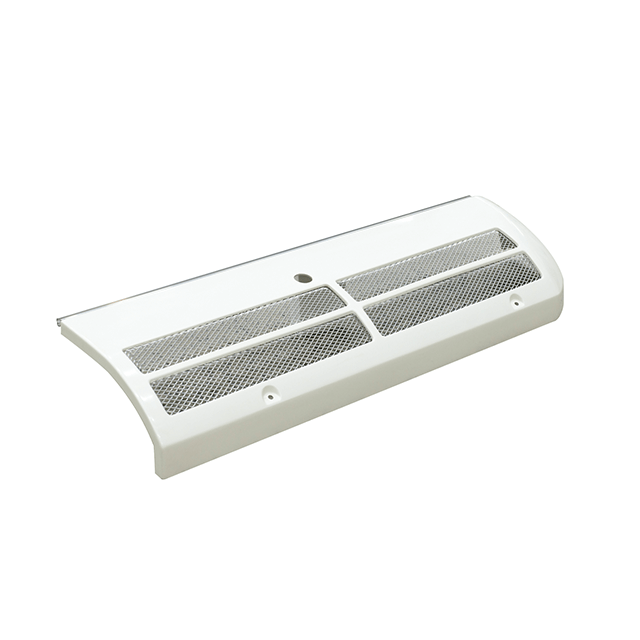

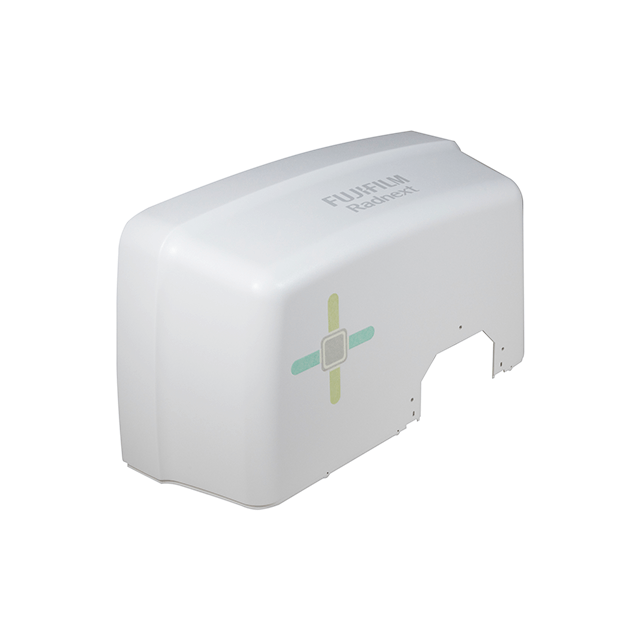

Diversified production process

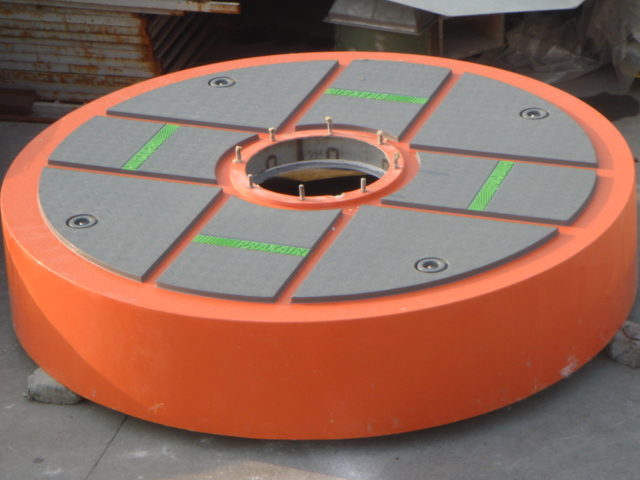

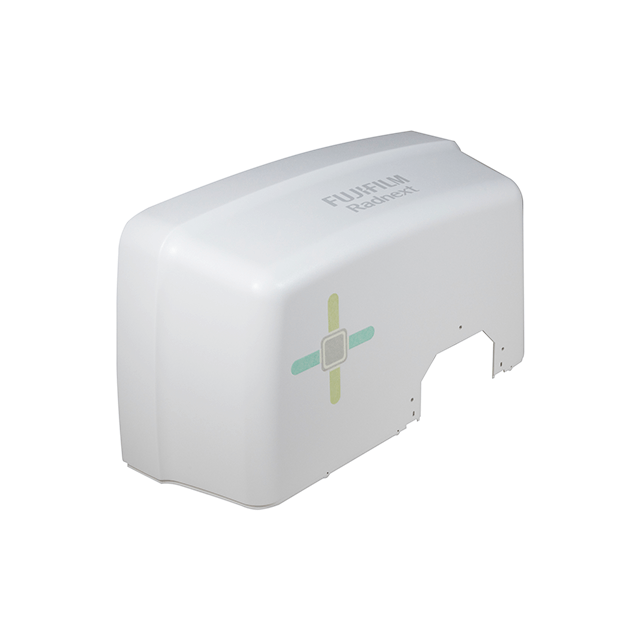

Professional R&D team, from development pipe design to finished products.

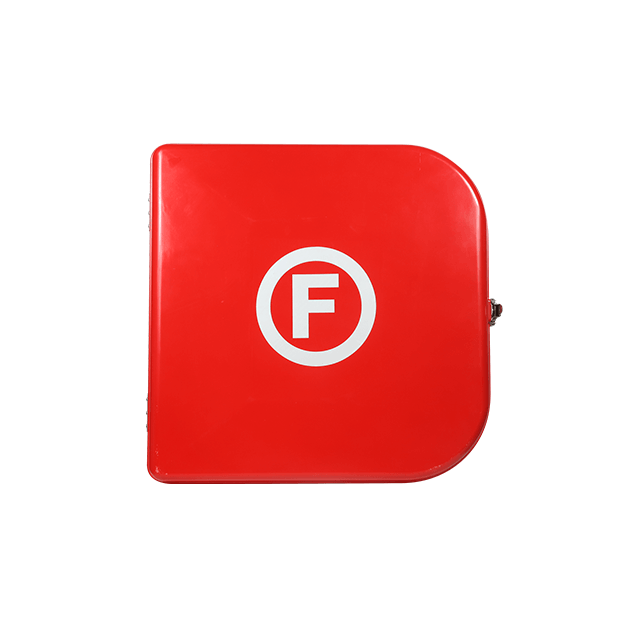

In the fast-paced world of food delivery, maintaining the right temperature for meals is more important than ever. Customers expect their orders to arrive hot and fresh, and businesses that fail to meet these expectations risk losing valuable clientele. One of the most effective solutions is investing in a high-quality fiberglass food delivery box. Designed for superior insulation, durability, and ease of transport, a fiberglass delivery box can be the key to ensuring customer satisfaction and business success.

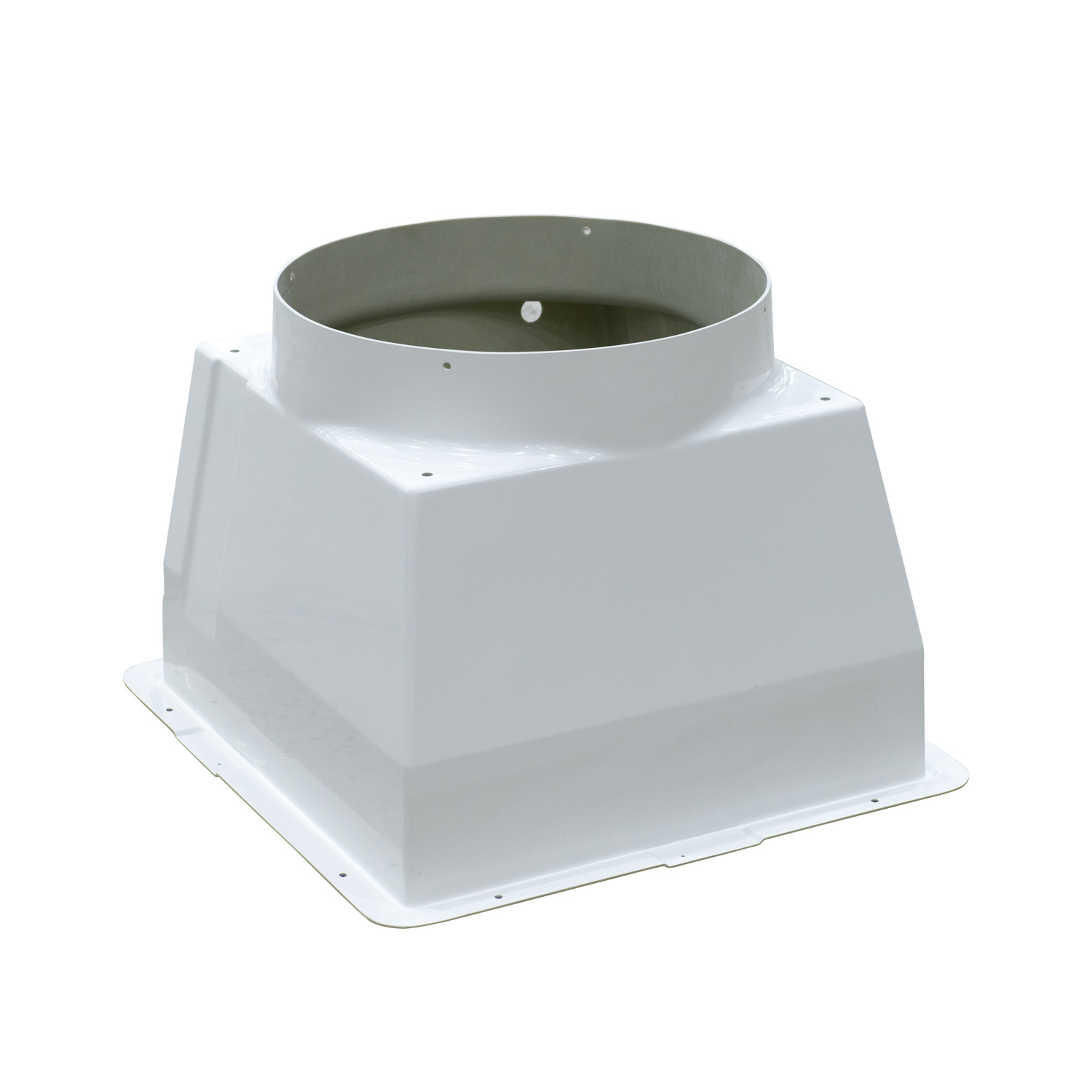

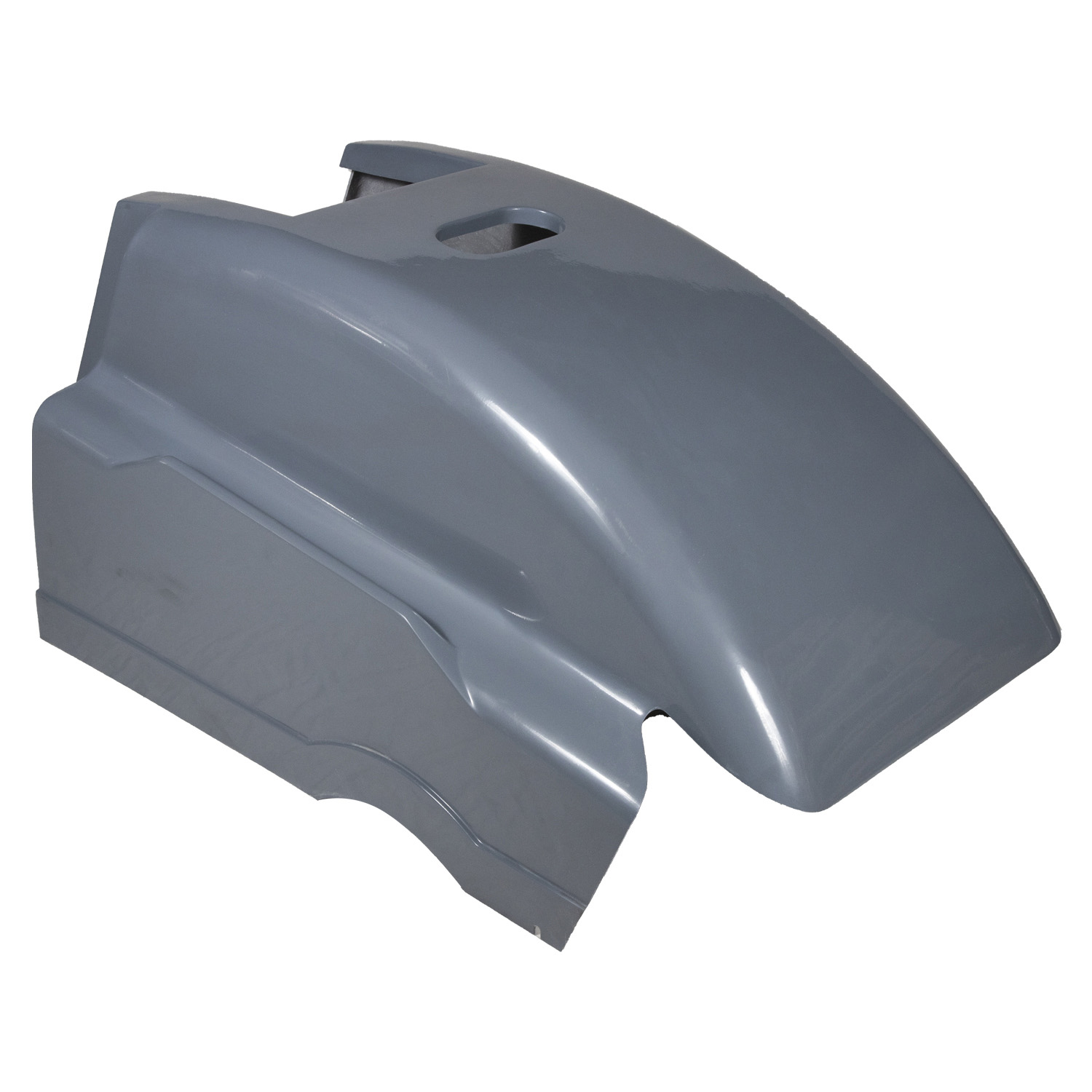

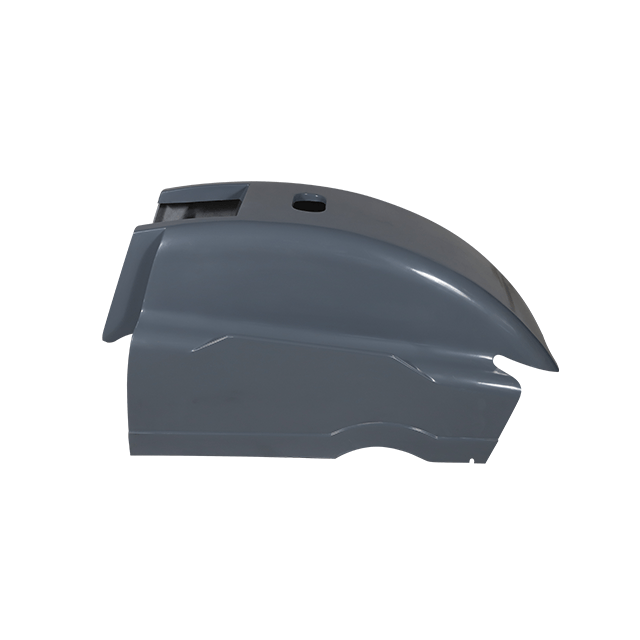

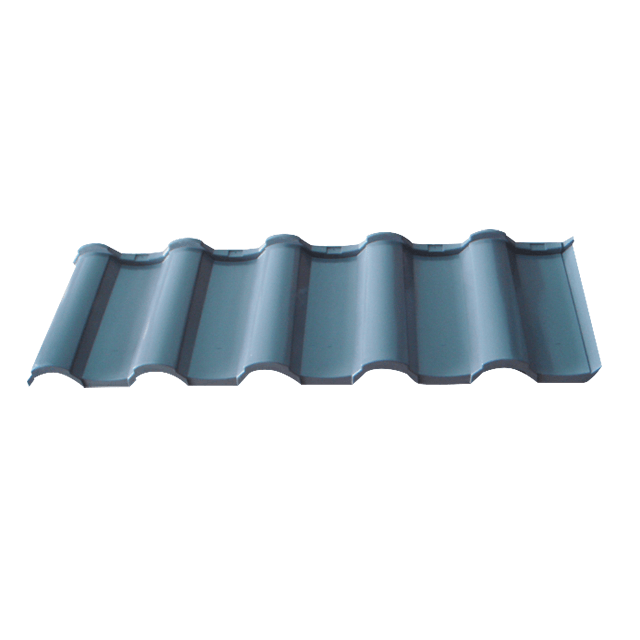

When it comes to durable, lightweight, and versatile storage solutions, nothing quite matches the reliability of a fiberglass box. Whether you’re outfitting a boat, upgrading a truck, managing electrical systems, or repairing a vehicle roof, fiberglass boxes are essential components across a wide range of industries. But what happens when you need to modify one? How do you knock out a fiberglass box safely and effectively without compromising its integrity?

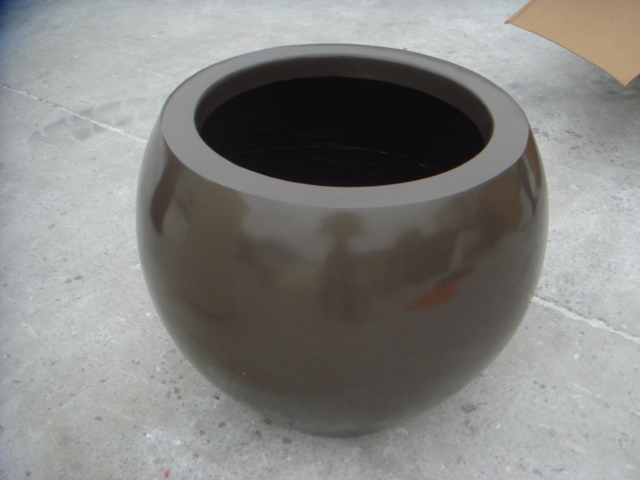

When it comes to choosing the right storage solution, businesses and individuals often find themselves comparing different materials. While plastic bins have long dominated the market, a growing number of industries are shifting towards more durable options like fiberglass bins. But why? In this article, we’ll explore an in-depth comparison between fiberglass bins and plastic bins, using real-world applications, product insights, and the latest trends in storage solutions. If you’re looking for the best option, whether for agriculture, industrial storage, or transportation, this guide will help you make an informed decision.

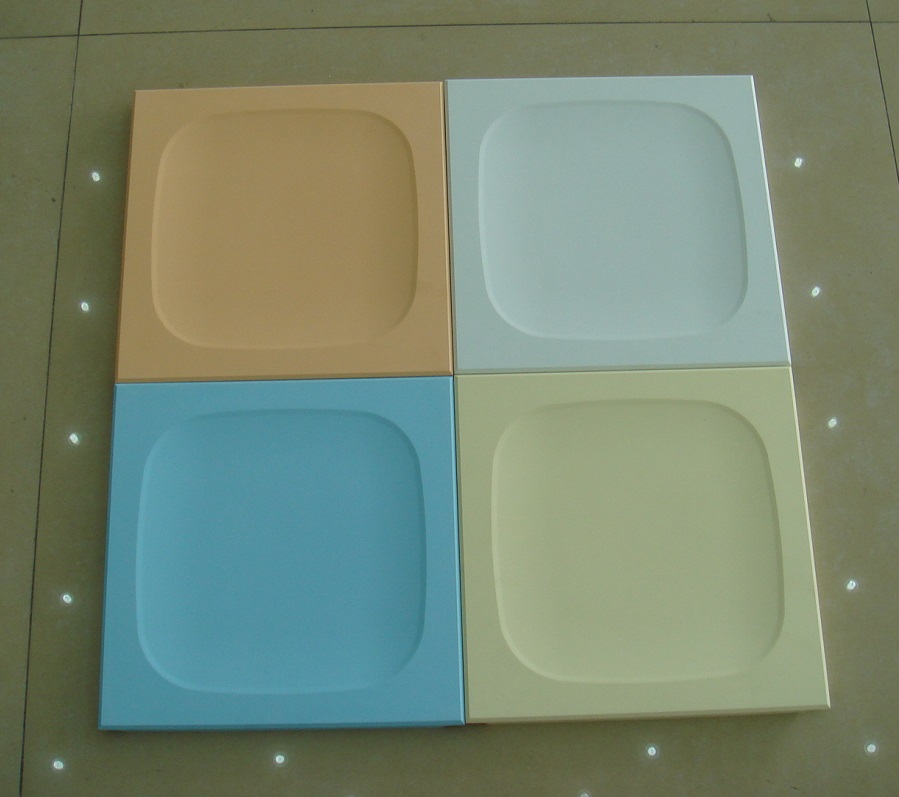

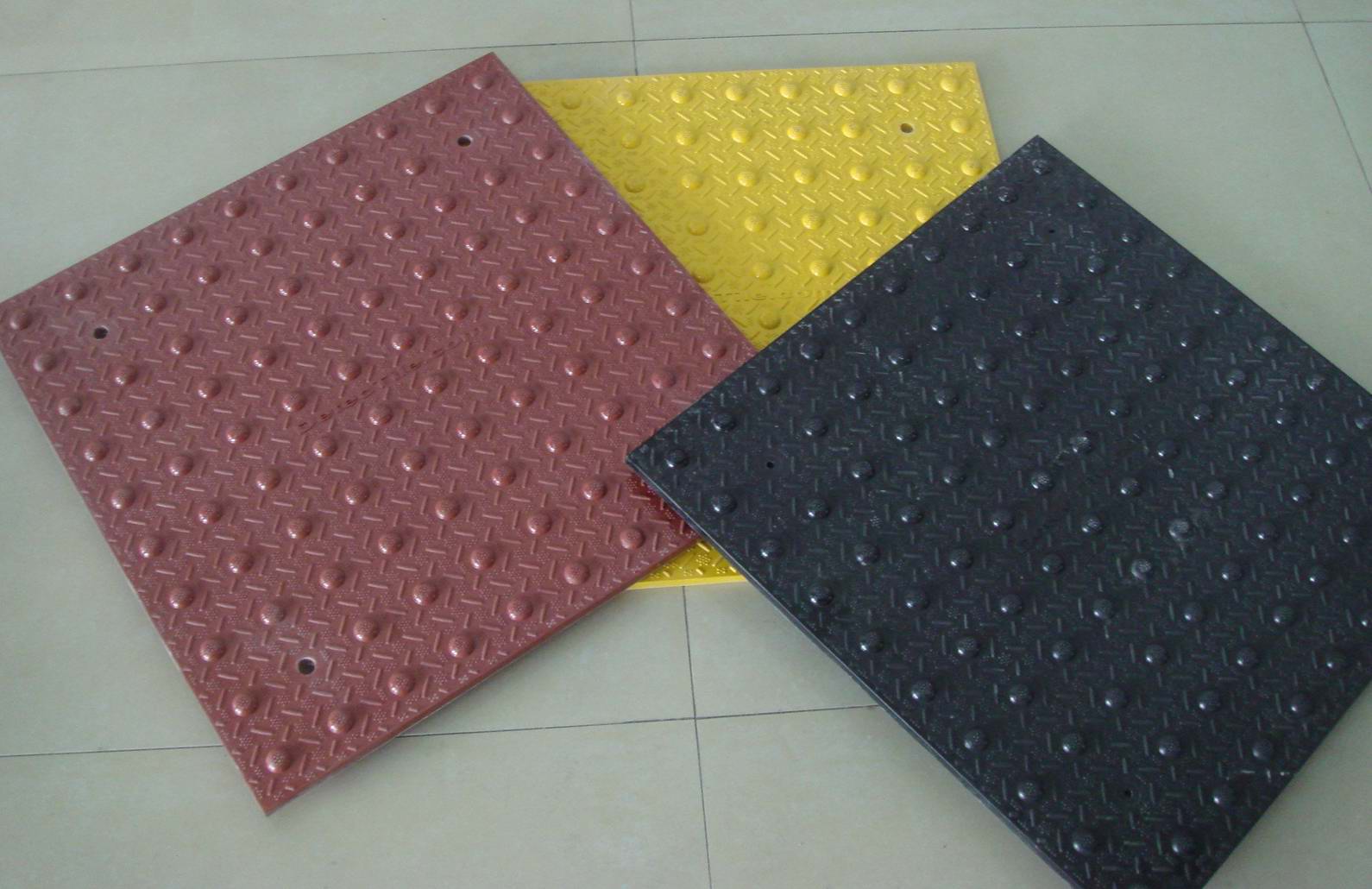

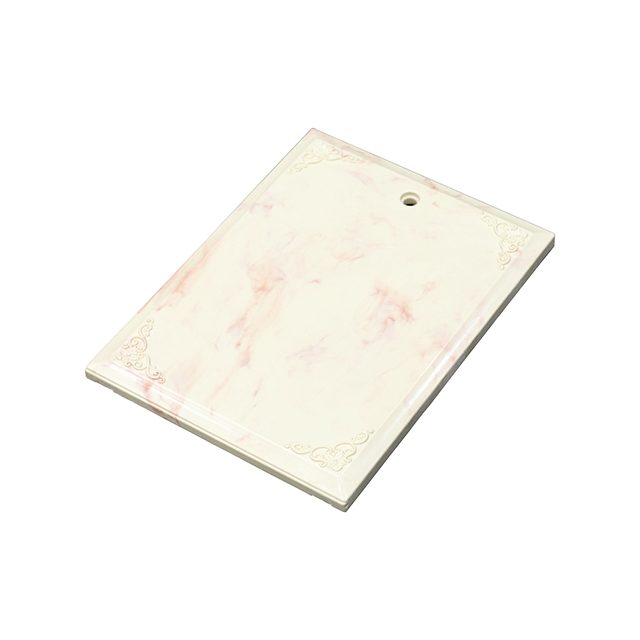

Fiberglass panels have become a popular choice in interior design for both homes and offices due to their exceptional combination of aesthetics, functionality, and durability.

Fiberglass panels have become a popular alternative to traditional building materials in modern architecture due to their impressive properties and versatility.

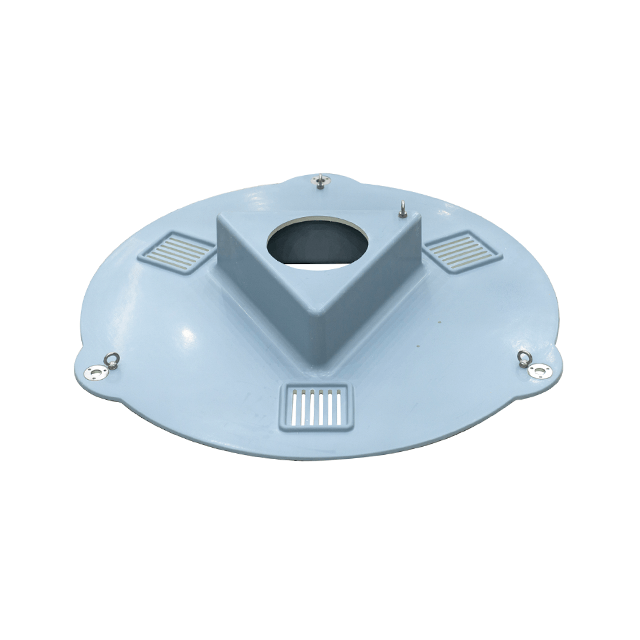

Fiberglass boxes are becoming increasingly popular in marine environments due to their many benefits, particularly in saltwater conditions.

In today’s fast-paced world, finding the right solution for storage and organization is essential. Whether it’s for home, industrial, or commercial use, the storage container you choose can impact your efficiency and convenience.